Category: 3D Printing Materials

-

Why Engineers Created PEEK — and Why It Changed Everything

For decades, engineering design was defined by compromise. Strength meant metal. Lightweight meant plastic. But the moment heat, chemicals, steam, or cyclic stress entered the equation, both options began to fail. PEEK was created to break that deadlock—and it quietly reshaped modern engineering. The Engineering Trade-Off That No One Could Solve Throughout modern engineering history,…

-

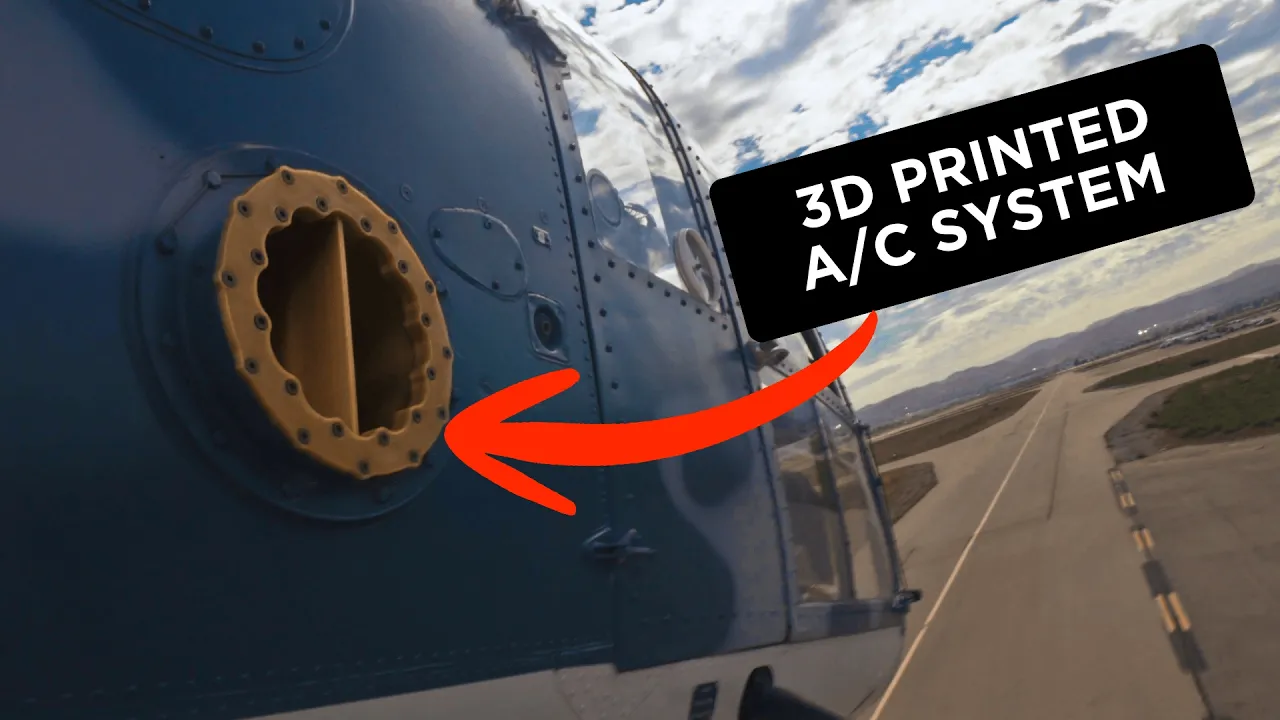

3D Printing a Helicopter AC Duct That Can’t Fail

A new helicopter AC Duct for what once carried missles. What sounds like a simple retrofit turned into a high-stakes aerospace engineering challenge that perfectly illustrates why additive manufacturing has changed what’s possible in aviation. The Engineering Constraint That Changed Everything The mission was clear: retrofit an air conditioning system onto a converted military helicopter.…

-

The Airplane Crash No One Should Ignore

Imagine your life depending on a piece of plastic with about the same heat resistance as a fast-food straw. That’s not a thought experiment—it’s exactly what happened when a single 3D printed component failed and caused an airplane crash on final approach. The Incident: Airplane Engine Failure at 500 Feet A highly experienced pilot, with…

-

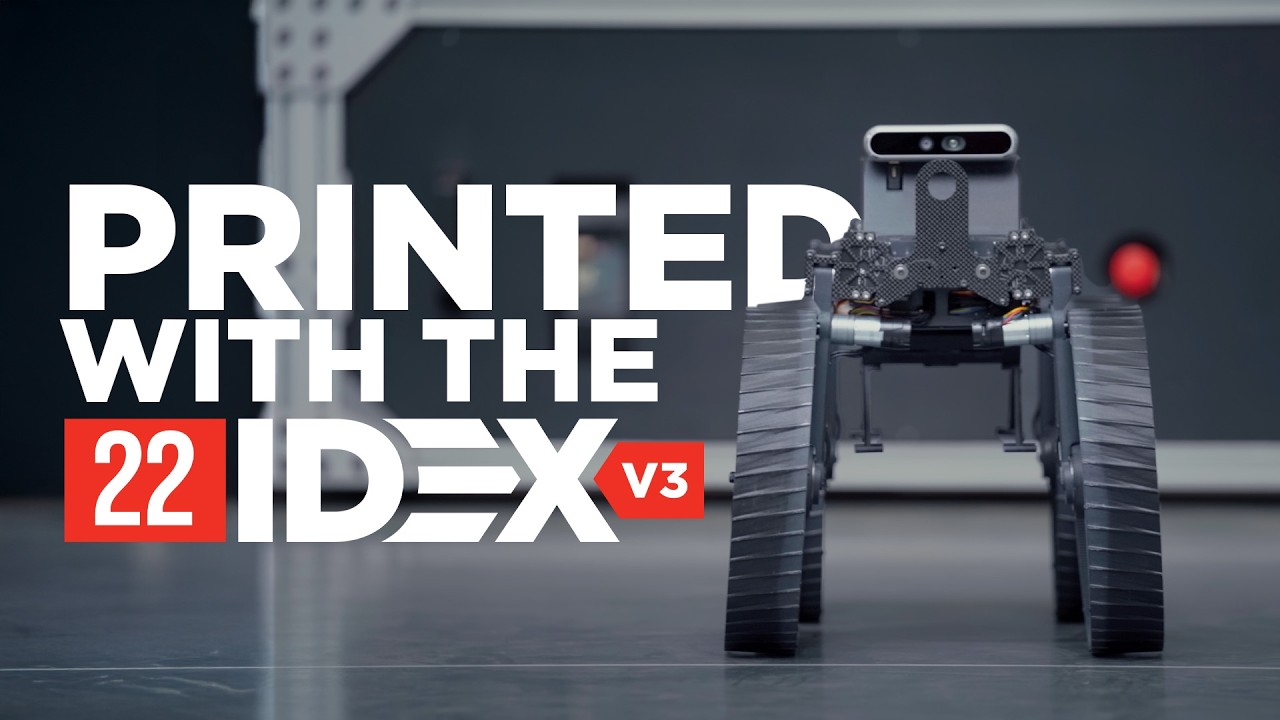

Tuning PEKK 3D Prints with Dual Nozzles on the 22 IDEX

Optimizing support removal with 3DXTech HTS material, Z-offset calibration, and nanopolymer adhesives for industrial-grade performance. Why This PEKK Print Needed More Than Standard Support When a customer requested a functional part for use inside an engine bay, it introduced tough challenges: exposure to oil, heat, and dripping fluids. The print demanded high mechanical strength and…

-

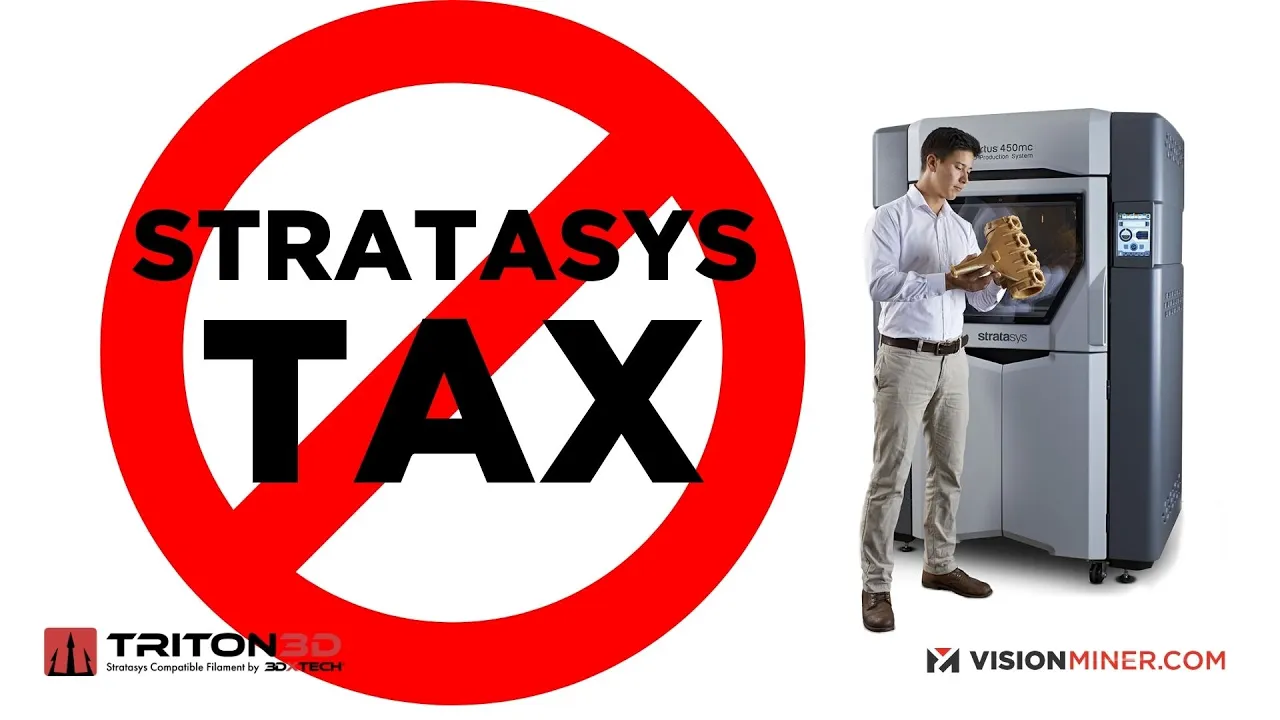

Save Big on Stratasys Materials with Triton 3D

Cut your material costs with Triton 3D by up to 60% without changing your workflow. The Problem with Stratasys Materials If you run Stratasys® 3D printers, you already know the pain—locked-in, proprietary cartridges with embedded chips that force you to buy OEM filament at sky-high prices. Once the programmed volume runs out, that cartridge is headed straight…

-

Polycarbonate Filament: The Ultimate Guide to 3DX Max PC

Polycarbonate isn’t your average hobby filament — it’s an engineering thermoplastic trusted in applications from riot shields to headlamp lenses. 3DX Max PC is as close as you can get to unfilled, pure PC in filament form. With a glass transition temperature of 147 °C and a heat deflection temperature of 135 °C under load, it’s one of the…

-

Nylon 12 vs Nylon 6 for 3D Printing: What You Need to Know

Dimensional stability or brute strength? We break down when and why to choose PA12 or PA6 for your next 3D print. What Is Nylon 12 (PA12)? Nylon 12, or PA12, is a high-performance polymer known for its dimensional stability, low moisture absorption, and ease of printing. It features longer molecular chains compared to Nylon 6,…

-

CFPA6 Filament: The Industrial-Grade Workhorse for Strong, Lightweight 3D Printed Parts

Lightweight. Rigid. Accessible. If you’re printing real-world functional components, Carbon Fiber Nylon 6 (CFPA6) should be on your radar. What Is CFPA6 and Why Does It Matter? CFPA6 stands for Carbon Fiber Reinforced Polyamide 6—a high-performance nylon composite infused with chopped carbon fiber. This combination results in a filament that is dimensionally stable, resistant to heat and…

-

Caltech’s CASTx Laboratory: Rewriting the Rules of Aerospace Design

From Mars rovers to flying ambulances, additive manufacturing at Caltech’s CASTx is rewriting the rules of aerospace design. A New Frontier: 3D Printing for Planetary Infrastructure Imagine sending robots to Mars not just to explore, but to build. At Caltech’s CASTx Laboratory, that’s more than a vision—it’s an active research initiative. Engineers are leveraging advanced 3D…

-

Glass Fiber is rapidly gaining ground—and for good reason

3D printing composites have revolutionized how we think about strength, rigidity, and thermal performance in additive manufacturing. Among them, glass fiber (GF) and carbon fiber (CF) reign supreme. While CF has long been a staple, GF is rapidly gaining ground—and for good reason. Glass Fiber: The Underdog with Surprising Strength Glass fiber is a silica-based,…

-

GF PEEK: Ultimate Guide to High-Performance 3D Printing Materials

Glass-Filled PEEK (GF PEEK) is redefining the limits of what’s possible in additive manufacturing. Here’s why this material is a game-changer across aerospace, automotive, energy, and electronics. What Is GF PEEK? GF PEEK, or Glass-Filled Polyether Ether Ketone, is a composite thermoplastic engineered for extreme performance. It’s essentially PEEK reinforced with 20–30% glass fibers by weight. While…

-

Unlock Advanced Engineering with CF PEEK: The Ultimate 3D Printing Material

Discover the capabilities, specs, and real-world performance of Carbon Fiber PEEK for advanced 3D printing applications. What is CF PEEK? CF PEEK stands for Carbon Fiber Reinforced Polyether Ether Ketone—a next-generation thermoplastic composite designed for extreme performance. As part of the PAEK family, it combines the resilience of PEEK with the stiffness of carbon fiber,…

-

Inside Caltech: 3D Printers Are Redefining Robotics and Aerospace

Take an inside look at the Caltech Center for Autonomous Systems and Technologies (CAST), where precision engineering, AI robotics, and industrial 3D printing come together to prototype the future of exploration, mobility, and autonomy. Caltech CAST: Where Vision Becomes Technology Few places on Earth have the same pedigree in aerospace innovation as Caltech. Home to…

-

Print Stronger, Pay Less: The PA6+CF Secret Markforged Doesn’t Want You to Know

Discover a high-strength, high-performance carbon fiber nylon filament that doesn’t lock you into a proprietary ecosystem. What is Obsidian PA6+CF? Obsidian PA6+CF is a carbon fiber-reinforced composite filament based on Nylon 6 (PA6), one of the most widely used engineering thermoplastics. Reinforced with less than 20% high-modulus carbon fiber, it delivers exceptional stiffness, strength, and…

-

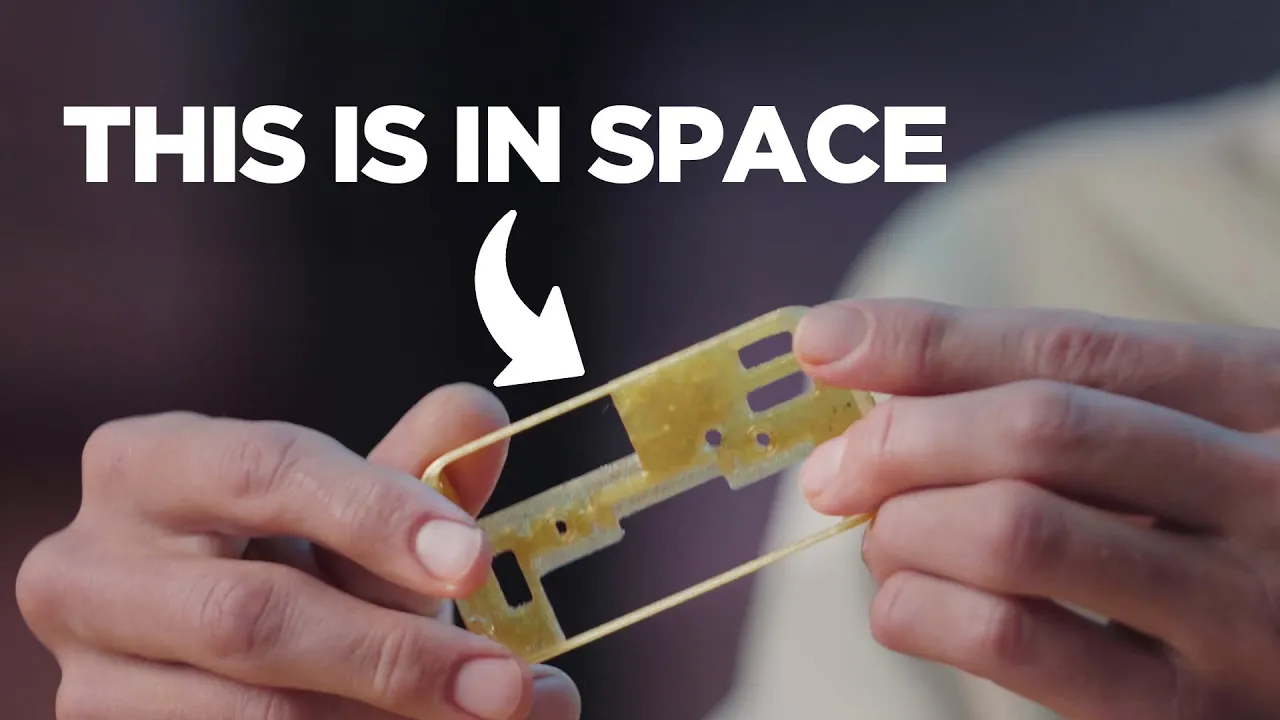

Why ULTEM 1010 Is the New Standard for 3D Printed Satellite Components

Discover how advanced 3D printing is revolutionizing satellite battery packs and high-performance thermoplastics like ULTEM 1010 for space applications. From Prototype to Orbit: ULTEM 1010 in Production One of the standout applications in aerospace additive manufacturing today is a 3D printed part used in a battery pack housing for satellites. The final production part, manufactured…

-

PSU Filament: The Hidden Champion of Industrial 3D Printing

Discover why PSU (Polysulfone) is redefining high-performance 3D printing in medical, aerospace, food, and industrial applications. What is PSU (Polysulfone)? PSU, or polysulfone, is an amorphous, high-performance thermoplastic engineered for extreme environments. Commercialized in the 1960s, it’s known for its heat resistance, dimensional stability, and exceptional clarity. Chemically built on aromatic rings, ether linkages, and…

-

NASA-Grade 3D Printing: Solving the Micro-Part Challenge with PEEK

A deep dive into the power of high-temp 3D printing in aerospace manufacturing with PEEK. High-Temp Parts in Space? Yes, Literally. What started as a mysterious call from Advanced Fuel Research (AFR)—a NASA contractor—evolved into one of the most technically demanding and rewarding projects in Vision Miner’s early history. The mission? Produce ultra-small, high-temp components…

-

ULTEM 9085 Filament: Aerospace-Grade Performance Made Easy

Discover why ULTEM 9085 (Thermax PEI 9085) is one of the most trusted high-performance filaments in aerospace, automotive, and industrial applications. What is ULTEM 9085? ULTEM 9085 is the trade name for a high-performance thermoplastic known as PEI (polyetherimide), originally developed by GE Plastics and now manufactured by SABIC. This specific grade is a blend…

-

3D Prints Under a Microscope: revealing the true nature of your 3D prints

Microscopic analysis reveals the true nature of your 3D prints—here’s what we found. Why Use a Microscope in 3D Printing? Looking at 3D printed parts under a microscope opens up a whole new world. From layer adhesion issues to print artifacts and surface inconsistencies, microscopic inspection reveals the invisible flaws and hidden features that can…

-

Unlocking the Strength of PEKK: A Superior Alternative to PEEK?

What is PEKK? PEKK (Polyether Ketone Ketone) is a member of the PAEK (Polyaryl Ether Ketone) family, known for its ultra-tough, high-temperature resistance and exceptional durability. Unlike PEEK, which has one ketone group per repeating unit, PEKK has two, affecting its crystallization and thermal behavior. Types of PEKK: Amorphous vs. Semi-Crystalline PEKK comes in different…